Having the latest and greatest inventions strategies, and systems is what manufacturers used to compete in the marketplace. As the technology keeps on advancing, every industry are trying to keep up with this advances which affect how they operates.

14 Manufacturing Trends in 2021

- Accessible Automation

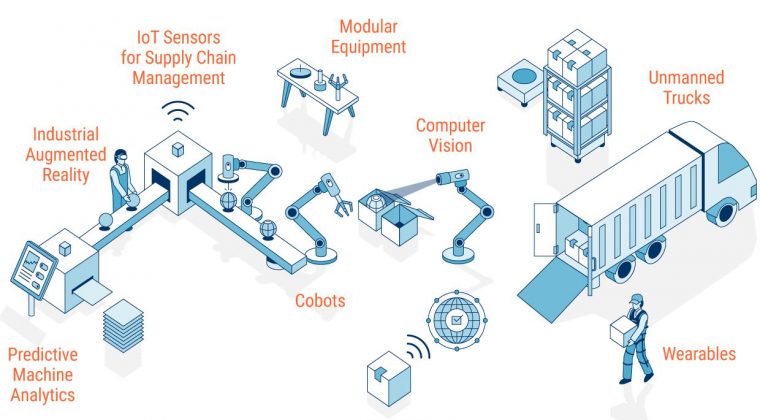

With new technology it is now possible to access automation in manufacturing world. Automation could reduce costs and optimize workflows. It is an easy to use robotic solutions, a user friendly Manufacturing Process Management (MPM) systems, and human robot collaborations. - Mobile Robotics

Autonomous mobile robots (AMRs) is one of the primary drivers of the manufacturing trend. Up to 41% over 2018 were shipments regarding robotics especially in non-automotive workplace. Today’s robotic technology is easy to use and user friendly which makes automation attainable for companies. - Internet of Things (IoT)

Connecting and monitoring various components of the company’s operations which enables the company to change, optimize, improve every facet of their manufacturing process and also gain insight regarding their manufacturing process. - Enterprise Resource Planning

Enterprise resource planning (ERP) technology is now getting widespread usage with it’s availability in cloud based SaaS options which makes it easier to deploy and more affordable for other small businesses in manufacturing industry. - Universal Connect-ability

With technologies and innovations not being billed as a one-size-fits-all solution and become a ‘universal connect-ability’ makes connecting with any device or system which d not limit the manufacturer’s options and opens up other ideas which are now possible to do. - Industry 4.0

Using and understanding the latest manufacturing technologies such as IoT, the cloud, advanced computers, robotics, and the human workforce. The functions available to combine and measure all in this together empowers the Industry 4.0. Which is now today’s current trend in the manufacturing industry. - Artificial Intelligence & Machine Learning

To enable the company to make the most of the access data by AI (referring to a computer system) processing it’s gathered research to recognize trends which helps manufacturers make data-driven decisions that leads to better production levels, increased profits, cheaper operations costs and better morale. - Predictive Maintenance

It is a maintenance technology hat could help manufacturers avoid downtime and less maintenance costs, made by IoT, AI and machine learning. - Supply Chain Technology

By managing he supply chain, manufacturers could save on cost while delivering products to customers. - Mobile Manipulators

It develops collaborative robots for the workforce, it’s used to automate other key areas of manufacturing with the collaboration of human workforce. - Additive Manufacturing

Which is commonly known as 3D printing which is a fast growing trend as a first & foremost a significant time and cost-saving tool. 3D printing enables cost effective mass production of metal parts that were previously impossible to make. 3D printing enables cost effective mass production of metal parts that were previously impossible to make. - Collaborative Robots (Cobots)

With Cobots being used in factories and warehouses it can get more work done, faster and more safely. It is built for the human workforce as a tool that helps improve overall efficiency in the workplace. - Automated Picking

It is a commonly used cobotic systems in manufacturing and logistics setting for picking which greatly improved the efficiency of the work. - Workforce Attraction, Retention, & Training

By minimizing the physically and demanding task to the workers, would attract good talent and keep them on the job. Collaboration between workers and robots reduces backbreaking and repetitive tasks.

Contact us for further information.