Industrial Intelligence

Applied

Our industrial applications bridge the gap between complex hardware and digital intelligence, providing robust frameworks for automation, monitoring, and control.

Mobile configuration of field devices in process industry

MPL's mobiLink interface revolutionises process industries by enabling real-time management of field devices using HART, FOUNDATION Fieldbus, and Profibus PA protocols. This mobile solution allows maintenance personnel to efficiently configure, monitor, and replace devices from tablets, enhancing predictive maintenance and reducing downtime, all in line with Industry 4.0 standards.

MPL – MAGBES Switches Applications

MPL's MAGBES switches are vital to NASA's SOFIA, the largest airborne observatory, which conducts infrared observations from altitudes over 12 kilometers. Mounted on a modified Boeing 747SP, SOFIA features a 2.7-meter telescope that offers significantly enhanced sensitivity and resolution. With a 20-year operational plan and around 160 flights per year, SOFIA aims to deepen our understanding of galaxy development and stellar evolution.

MPL – Rugged CEC-14 Applications

MPL's CEC 14-1, designed for extreme conditions at 35 km altitude, controls a portable X-band weather radar that detects precipitation up to 200 km away, operating in temperatures as low as -80°C. Equipped with six serial ports and two LAN ports, the CEC 14 addresses the demand for advanced weather management tools, supporting applications in watershed management, flood protection, and military operations.

Palm Oil Tank Farms Ready For Digitalisation

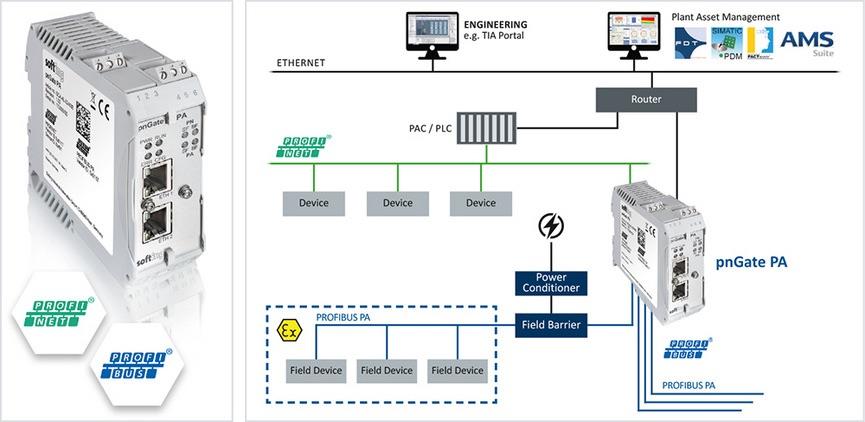

DNR Process Solutions has successfully integrated Profibus PA segments directly into Ethernet control systems at a large palm oil tank farm in Indonesia, utilising Softing's pnGate PA gateway. This seamless integration enhances real-time data transparency and inventory management, crucial for efficient operations in the palm oil industry. The implementation supports the digitalisation of processes, aligning with Industry 4.0 standards and facilitating improved decision-making and maintenance scheduling.

Softing – Gateway As A Bridge To A Future-Proof Process Landscape

Softing's pnGate PA gateway enables seamless integration between PROFIBUS PA segments and PROFINET control systems, enhancing flexibility and performance in process manufacturing. It allows for gradual upgrades without requiring specialised IT expertise, ensuring reliable operation and increasing the number of connected devices. The pnGate PA is part of a broader suite of digitalisation solutions supporting modern manufacturing processes.

Softing – Getting A Handle On ‘Industrie 4.0‘

Softing's dataFEED Secure Integration Server simplifies IT/OT integration for 'Industrie 4.0' by optimising data exchange, reducing complexity, and enhancing security. It uses OPC UA technology for seamless communication between production and management systems, offering interface abstraction, data aggregation, and centralised security management.

Softing – Greater Efficiency With ‘Industrie 4.0‘

Softing’s uaGate SI gateway enables KraussMaffei Technologies to enhance production efficiency and prevent downtime by automating machine condition monitoring. Using the open OPC UA standard, it connects machine control systems to IT networks, ensuring secure, real-time data collection. The solution also provides robust security features and supports both modern and legacy machinery, laying the groundwork for proactive condition monitoring.

Solutions For Digital Process Automation – WATER AND WASTE WATER

Automation solutions, like Softing’s dataFLOW gateways and mobiLink, help water utilities improve operational efficiency and meet strict environmental regulations. The dataFLOW gateways enable seamless integration of field devices into control systems for real-time monitoring, while mobiLink provides a mobile tool for configuring and maintaining devices across multiple protocols, reducing downtime and ensuring system compliance.