IIoT has been crucial for all industries, but as manufacturing engineers, the focus on IIoT impact stays aligned on the way device, plant, and internet connection continue to improve and elevate the productivity of the supply chain as a whole.

Docker container is essential in the process for safer software delivery. It’s true that applications today have so many tiers and layers that interconnecting and interoperating systems are taking longer time than expected.

Within the manufacturing line, every single step of the process relies on a database and web server, especially when everything is stored in the cloud. The true nature of IIoT is turn-key as a storage solution, and the bottleneck to this situation is that when a plant’s system is not strongly and vehemently structured, any breach, compromisation, and errors can take everything down.

With factories becoming significantly digitalised, cyber-physical-system and IoT are resolving and innovating software management at another level of speed. Deployment, configuration, and integration are considered important, or even of most importance. With a docker container, distributing, deploying, and managing configurations of multiple software modules will be simplified between multiple locations in different platforms, protocols, and programming languages.

A focal point of docker implementation is to mirror the symbiosis of human-robot collaboration. Enabling exploration, research, and development of best productivity of human-robots advantages and utilisation, whether it is done alone, together, or simultaneously.

Sources indicate that there are approx. 7.74 billion connected IoT devices with over 357% increase forecasted in the next 7 years.

Everything from and including intelligent field devices or human-generated data, temperature sensors, pressure meters, level sensors, and flow meters, can provide plant operators with solid plant health information.

There are commonly a couple of ways to approach IoT data management. Attaching computing power to hardware by embedding microprocessors can help low-power devices with limited communication capability or capacity. For example, industrial IoT sensors to plant machinery. Another approach is to rely on heavy hardware processors. For example, a self-driving car.

Transferring, collecting, and centralising data to systems, organisations, hardware, and parts from embedded devices can be managed only with decentralised parts of data processing.

With connectivity, continuity, and cybersecurity as most manufacturer’s Achilles heels, the docker container can be a very stable solution.

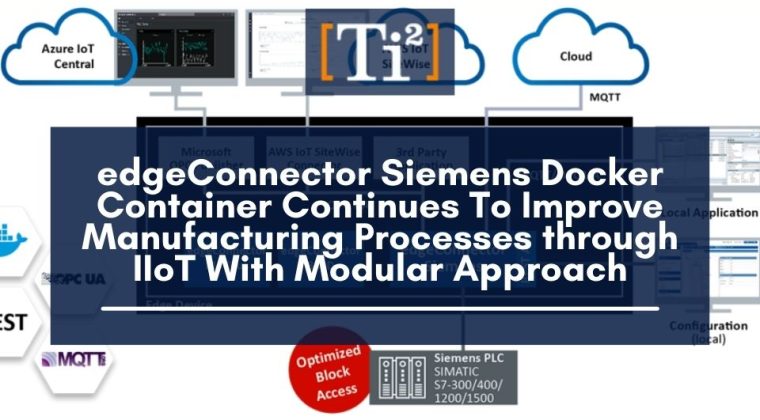

Softing Industrials’ docker container – edgeConnector Siemens are highly recommended to help flexible deployment options.

Ensuring that IoT devices are connected to the system is important, but it’s also important to make sure it has enough power to run and provide coverage for the network and the cloud. Containers can usually run on both client and server as well as admins, so developing software, and managing updates for endpoint devices are easier to provide reliably IoT implementations.

Softing Industrial’s docker container uses a modular approach that helps plants and manufacturers rapidly deploy and manage complex applications with fewer computing resource consumption compared to virtual machines.

edgeConnector Siemens connects Siemens SIMATIC S7-300/400, and S7-1200/1500 controller and provides access to data via an OPC UA server interface. In addition, the data can also be transmitted to MQTT brokers using MQTT. As a docker container, it also offers flexible deployment options, for example on devices running Azure IoT Edge or AWS IoT Greengrass.

With a docker container, your supply chain will experience:

- Cost decrease for longer-term performance

- Cloud partner/provider flexibility

- Scalable to services and demands in rapid speed

With containers, you are reducing the load of your IoT system, improving overall reliability and efficiency during manufacturing processes.

To learn more about what we do and how we can help your interoperability requirements, please click projects, products & services.

Ti2 is currently very focused on working with its global partners to secure stock and avoid long delay times in delivering products to their customers. Together with our trusted partners, we are here to provide solutions.

Please click here to email us your inquiry, we would like to hear from you.

Article inspired by techgenix, transformstatistc, Softing, HART, Elsevier, and Ti2.