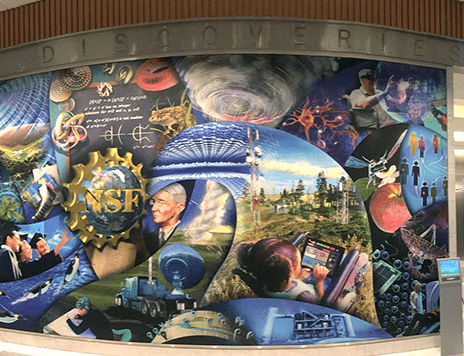

The Future Manufacturing

The National Science Foundation has created a research grant for manufacturing for leading innovators the funding to research and develop advance the way manufacturing operates for better outcomes in productivity and operations.

The program is to support fundamental research and education of a future workforce to overcome scientific, technological, educational, economic and social barriers in order to enable new manufacturing capabilities that do not exist today.”

The industry has seen manufacturing evolved dramatically over recent decades but as we step forward, making further huge leaps into technological advances and towards Industry 5.0, this program seeks to drive us forward through to this next evolution. Research is vital for advancement in manufacturing for instance automotive manufacturers have been researching the capabilities of interconnected, live-data devices for close to a decade plus and invested US$183 billion to create the IoT. Thus, research is vital to the future of manufacturing.

The grants provided through Future Manufacturing are for seeking out new manufacturing capabilities as well as new tools and products such as 3D printing applications (additive manufacturing) but the seed grants in particular are encouraging new social structures, educational access and standards, and opportunities for individuals of any and all backgrounds to enter the industry of manufacturing.

The Types of Research NSF funds

The grants offered by the NSF through Future Manufacturing are focused on the following areas:

Cyber Manufacturing

Aimed at the convergence of computing and manufacturing, future cyber manufacturing capitalizes on research opportunities that will radically transform manufacturing concepts. Breakthroughs in predictive analytics, machine learning, wireless communication, automation, artificial intelligence, cyber-physical-human systems, 3D printing, industrial IoT, and computing systems of the fourth industrial revolution provide important incentives to reconceptualize what it means to operate in manufacturing.

Cyber manufacturing provides customization, democratization or access to platforms, security, algorithms, modelling, analytics and more to almost every industry in manufacturing. By acting as a service, cyber manufacturing can meet a business right where it is with opportunities like AI-inspired manufacturing of quantum material architectures, modular construction assisted by robots, or bioinspired swarm manufacturing.

Eco Manufacturing

Enabling holistic processes to encompass a manufacturing products’ material lifestyle as well as account for environmental impact, cost effectiveness and energy consumption. Eco manufacturing provides processes like recycling, circular economy, reprocessing, bio mechanisms and efficiency platforms.

As the NSF puts it, “Fundamental research could enable manufacturing processes that are designed from the start to produce products that degrade naturally or on cue or can be repurposed without harmful by-products and without reliance on technologies that are potentially harmful to the environment and society at large.” Hence, the NSF implemented this area of research to ease the burden that we are placing on the natural processes around us.

Biomanufacturing

Biomanufacturing research relates mostly to integrated biological processes and proteins. Biomanufacturing provides cell-free or customizable proteins through robust, connected or scalable processes with the intent of enhancing human life. Examples of biomanufacturing include generating functional materials in cells to regrow nerves or tissues, and mass production of extracellular vesicles for therapeutic delivery.

“The seamless integration of new biological knowledge with manufacturing technology during product and process development may overcome long standing barriers to scalability of new types of biomanufacturing platforms,” explains the NSF. This is the cutting-edge manufacturing technology that will drive us into future prosperity.

Networks

This relates mostly to the tools and systems in place to enhance the potential for the above manufacturing sectors. Examples of an innovative network in manufacturing would be the rapid scaling of production for crisis response i.e., immediate response to the need for facemasks.

With interconnectivity not just on the rise but almost as a mandatory operating procedure, the networks of industry will play a crucial role in filling needs for consumers. Research in this area will radically rethink where and how manufacturing occurs. Yes, we’re as connected as we’ve ever been, but the networks created from this research will take us to an entirely new level.

For more information on this topic, go to propelplm.com/blog/the-future-of-manufacturing

For more information on how Ti2 can help your organisation, please do contact us.