Overview

Prototype Controls and Development for an Australian Healthcare Company

This Australian based company is developing environmentally friendly infection control solutions for the healthcare industry. Initial products include a device specifically designed to disinfect reusable medical instruments such as interactivity and surface ultrasound probes.

Ti2 assisted this company on a number of levels including:

- Electronics, Control Software, and Operator interface development for Prototype units

- Development of a marketing device

- Control and Data collection for life testing systems

- Manufacturing Test Systems – Testing of sub-assemblies and final assemblies

Completion Date

June 17, 2016

Project Details

The time frame for this project was very tight. A working prototype was required for a number of reasons including proof of concept, laboratory trials and investor confidence.

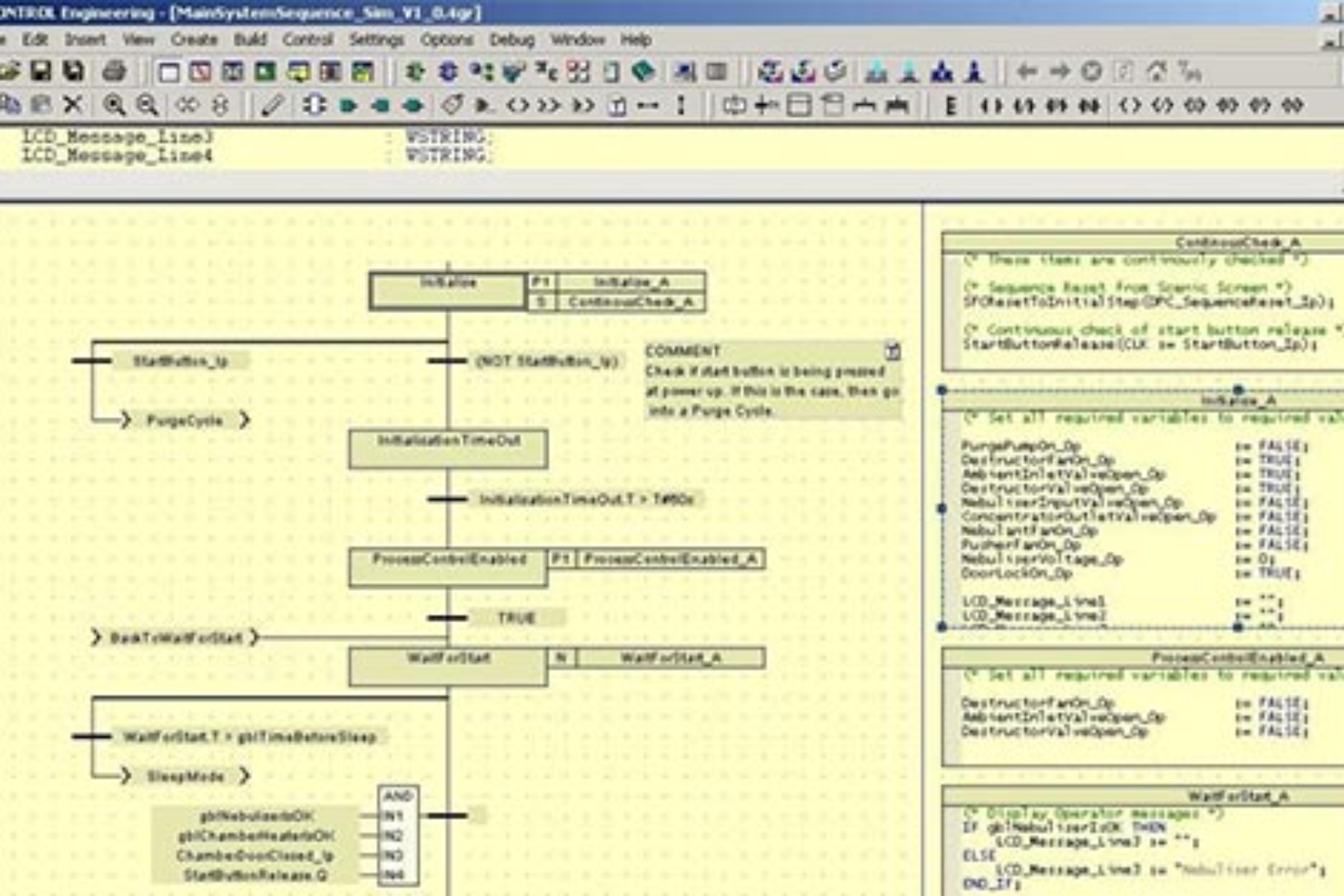

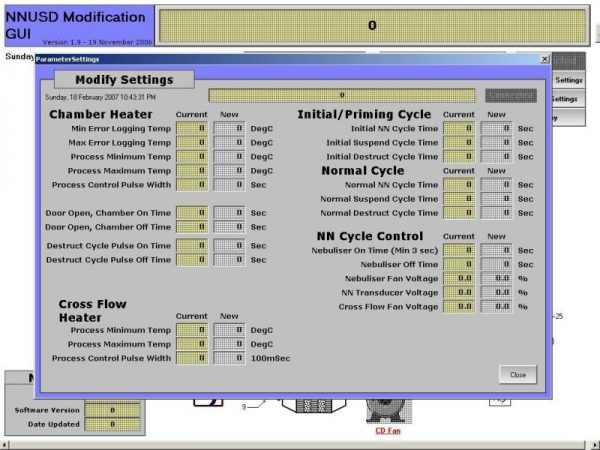

Included in the project brief was the need to develop specialised electronics boards, Automation Code, and Graphical User Interface (GUI) to allow testing and changing of system parameters.

Using off the shelf components for control and GUI drastically shortened the development time thus achieving the very tight time lines allowed for this project. It also gave flexibility for changing requirements during the project. Product included:

- 4Control (IEC61131-3) Software for PC and Ethernet controller

- Wago Ethernet controller (With 4Control Firmware) with I/O modules

- Scenic Operator interface

- Some Fast development PCB development tools

nano5The time frame for this project was very tight. A working prototype was required for a number of reasons including proof of concept, laboratory trials and investor confidence.

Included in the project brief was the need to develop specialised electronics boards, Automation Code, and Graphical User Interface (GUI) to allow testing and changing of system parameters.

Using off the shelf components for control and GUI drastically shortened the development time thus achieving the very tight time lines allowed for this project. It also gave flexibility for changing requirements during the project. Product included:

- 4Control (IEC61131-3) Software for PC and Ethernet controller

- Wago Ethernet controller (With 4Control Firmware) with I/O modules

- Scenic Operator interface

- Some Fast development PCB development tools

nano6Of vital importance to the success of this project was the use of proper development philosophies with the customer which included:

- FMEA (Failure Modes and Effects Analysis)

- Properly reviewed requirements documents based on FMEA’s

- Design reviews for both hardware and software at several stages

- GAMP philosophies throughout the project

Working closely with the R&D engineers and the product design team, the prototype was ready for laboratory trials in under 2 months. This lead to the development of a marketing device used for overseas exhibitions and developing customer interest.

Extensive use of SFC (Sequential flow chart) and Structured text made the programming rapid to implement, simple to fault-find, understood by varying disciplines, and allowed quick modifications to code. This style of coding is also known for its “less errors first time” results.