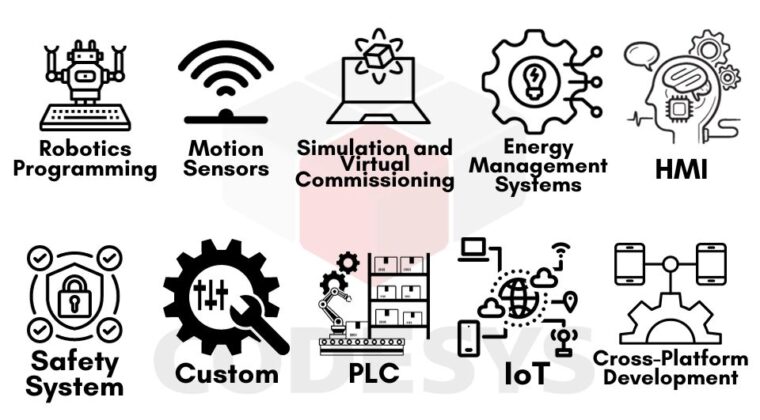

CODESYS has emerged as a cornerstone for companies seeking to enhance efficiency, precision, and adaptability in their automated processes. This blog delves into ten common applications of CODESYS, ranging from the programming of Programmable Logic Controllers (PLCs) to motion control systems, Human-Machine Interface (HMI) design, safety systems, industry integration, and more. Each application is accompanied by a concise and insightful guide to the associated control logic, providing a practical understanding of how CODESYS empowers industries across the spectrum.

Our aim is to explore and expose the full potential of CODESYS for customised solutions, robotics programming, simulation, energy management, and cross-platform development.

10 Applications and Control Logic

- Programmable Logic Controllers (PLCs): One of the primary applications of CODESYS is in the programming of PLCs. Companies use CODESYS to develop control logic for PLCs, which are essential components in automated manufacturing and industrial processes.

Control Logic: Develop a CODESYS program to manage a PLC in automated manufacturing. Implement start/stop controls, sequence logic for production, and error handling routines. Utilise CODESYS structured text and ladder logic to ensure efficient and reliable operation.

- Motion Control Systems: CODESYS provides advanced motion control functionalities. Companies leverage these features for precise control of motors and actuators in applications such as robotics, CNC machines, and other motion-intensive processes.

Control Logic: Implement advanced motion control using CODESYS for a robotic system. Define motion paths, coordinate multiple axes, and integrate feedback systems for precise control. Leverage the CODESYS SoftMotion library to facilitate smooth and synchronised movements.

- Human-Machine Interface (HMI) Design: CODESYS allows for the creation of HMIs, enabling companies to design intuitive interfaces for operators and engineers to monitor and control industrial processes. This involves creating graphical user interfaces for visualisation and interaction.

Control Logic: Create an HMI interface in CODESYS to monitor and control industrial processes. Develop graphical user interfaces with CODESYS Visualisation to display real-time data, status indicators, and interactive controls for operators and engineers.

- Safety Systems: In industries where safety is a critical concern, CODESYS is used to program safety functions. This includes implementing safety features in machinery and processes to comply with industry safety standards.

Control Logic: Program safety functions using CODESYS to ensure compliance with industry standards. Implement emergency stop routines, safety interlocks, and monitoring systems to safeguard machinery and processes. Use safety-rated input and output devices for fail-safe operation.

- Industry 4.0 and IoT Integration: With the rise of Industry 4.0 and the Internet of Things (IoT), companies use CODESYS to integrate their automation systems into smart, interconnected networks. This involves connecting PLCs and other devices to collect and analyse data for improved efficiency and predictive maintenance. Read more about CODESYS Runtime Toolkit for IoT-enabled Industrial Automation.

Control Logic: Integrate Industry 4.0 principles using CODESYS to enable connectivity and data exchange between PLCs and IoT devices. Implement protocols like MQTT and OPC UA for seamless communication. Develop CODESYS programs to collect and analyse data for predictive maintenance and improved efficiency.

- Customised Solutions: CODESYS allows for the development of customised automation solutions tailored to specific industrial applications. Companies can create bespoke automation systems that meet their unique requirements.

Control Logic: Develop customised automation solutions in CODESYS tailored to specific industrial applications. Utilise IEC 61131-3 programming languages to create control algorithms and implement specialised functions based on unique requirements. Ensure modularity for scalability.

- Robotics Programming: In industries relying on robotic systems, CODESYS is employed for programming the robotic controllers. This includes defining motion paths, coordinating multiple axes, and ensuring synchronisation in complex robotic applications. Read more about CODESYS and CNC Robotics here.

Control Logic: Program robotic controllers using CODESYS to define motion paths, coordinate movements, and implement synchronisation. Leverage advanced kinematics and motion control features in CODESYS to optimise robotic operations. Ensure precise control for complex robotic applications.

- Simulation and Virtual Commissioning: CODESYS supports simulation and virtual commissioning, enabling companies to test and validate their control logic in a virtual environment before deploying it to the actual machines. This reduces downtime and enhances system reliability. Read more about CODESYS simulation and free licensing here.

Control Logic: Use CODESYS simulation tools to create virtual environments for testing and validating control logic. Develop realistic scenarios to simulate machine behavior. Verify the reliability and efficiency of the control logic before deploying it to the actual machines.

- Energy Management Systems: For industries focused on energy efficiency, CODESYS is used to develop energy management systems. This involves implementing control strategies to optimise energy consumption in various processes. Read more about AI in Energy Management Systems here.

Control Logic: Develop energy management systems in CODESYS to optimise energy consumption in industrial processes. Implement control strategies to regulate power usage based on production demands. Utilise CODESYS libraries for energy monitoring and analysis.

- Cross-Platform Development: CODESYS is platform-independent, allowing companies to develop and deploy their automation solutions on various hardware platforms. This flexibility is advantageous for industries with diverse automation needs.

Control Logic: Create CODESYS programs that are platform-independent, allowing deployment on various hardware platforms. Utilise features like platform abstraction and standardised I/O interfaces to ensure seamless operation across diverse automation setups. Implement coding practices for compatibility and scalability.

Conclusion

As we draw the curtains on our exploration of the ten common applications of CODESYS and their respective control logic guides, it’s evident that CODESYS is more than just a programming environment; it’s a catalyst for innovation, efficiency, and adaptability in industrial automation. From the precision-driven world of PLC programming to the intricacies of advanced motion control and the seamless integration into Industry 4.0/5.0 networks, CODESYS stands as a versatile and indispensable tool for industries worldwide. The ability to create customised solutions, program robotic systems, simulate complex scenarios, optimise energy usage, and deploy across diverse hardware platforms showcases the breadth of its capabilities.

As we navigate the evolving landscape of automation, CODESYS continues to be at the forefront, empowering industries to not only meet today’s challenges but to anticipate and shape the future. Whether you are fine-tuning control logic for a conveyor belt or orchestrating the intricate dance of robotic arms, CODESYS remains the cornerstone for unlocking the full potential of automation, ensuring a connected, efficient, and innovative future for industrial processes.

Contact us HERE if you’re interested in implementing CODESYS in your industrial projects to unlock its benefits and drive innovation in your industry.

Or to learn more about what we can do to help your automation requirements, please click projects, products & services.

Ti2 is currently very focused on working with its global partners to secure stock and avoid long delay times in delivering products to their customers. Together with our trusted partners, we are here to provide solutions for your needs.

Please click here to email us your inquiry, we would like to hear from you.