Softing Industrial – echocollect e – Multiprotocol Gateway

Versatile Application Gateway for Machine-Database Data Integration

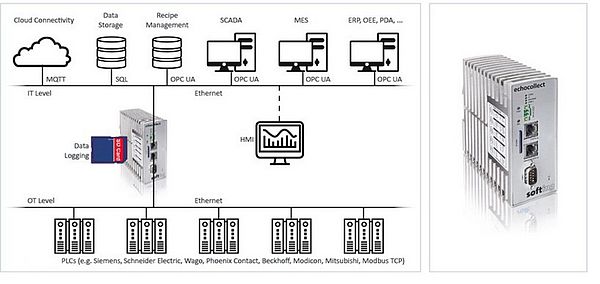

As an industrial multiprotocol gateway, echocollect e offers a modern solution for further processing of process data. The addition “e” in the product name stands for Ethernet, since the gateway only supports the connection to PLCs via TCP/IP protocols. echocollect e supports local data logging and enables a bidirectional real-time connection between controllers and databases, direct OPC UA integration and cloud connection via the MQTT interface.

The advantage of the NetCon configuration software is the high degree of customization options at protocol level.

As basic functionality, five PLC connections and MySQL as database driver are available. Extension licenses are available for the use of MQTT, OPC UA, data logging on SD card (including Store&Forward), the support of 15 PLC connections and further databases such as Oracle and Microsoft SQL.

Visit Softing