(instead of AC – Alternating Current)

In my recent trip to Germany I saw the trend that factories are switching from DC to AC… But why?

It’s essential to note that the decision to switch to DC power in a smart factory depends on the specific requirements, technology infrastructure, and goals of the facility. The benefits mentioned above may not apply universally to all scenarios, and the choice between AC and DC power depends on the particular use case and design considerations.

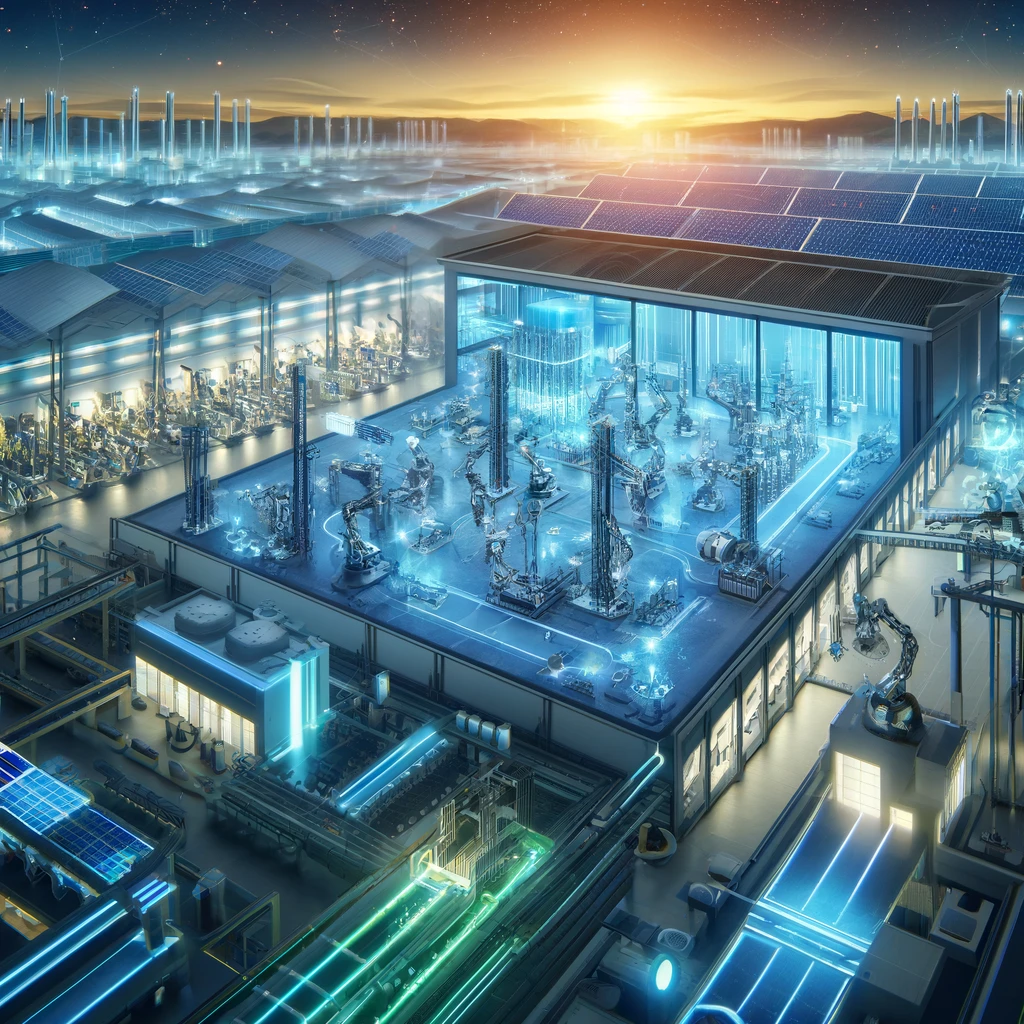

Integrating DC power with solar energy in a smart factory can offer several advantages, aligning with the global trend toward sustainable and renewable energy solutions.

Here are some benefits and considerations for using DC power with solar power in a smart factory:

1. Efficiency in Power Distribution: DC power distribution can be more efficient for certain types of loads and devices, particularly those that operate on low-voltage DC. It eliminates the need for conversion between AC and DC, which can reduce energy losses in the distribution system.

2. Integration with Renewable Energy Sources: DC power is often used in conjunction with renewable energy sources such as solar panels and batteries, which inherently produce DC electricity. By using DC power in smart factories, it becomes easier to integrate these renewable sources directly into the power system, promoting sustainability.

3. Power Consumption of Electronic Devices: Many modern electronic devices, including sensors, actuators, and other smart factory components, operate on DC power. Using DC throughout the system can eliminate the need for additional power conversion, making the overall system more efficient.

4. Reduced Electromagnetic Interference (EMI): DC power systems typically produce less electromagnetic interference compared to AC systems. In sensitive manufacturing environments where precise control and communication are crucial, reducing EMI can be advantageous.

5. Improved Control and Automation: DC power systems can provide better control and automation capabilities, especially in applications where variable speed drives are used. This is particularly important in smart factories where precise control over machinery and processes is essential.

6. Data Centres and Information Technology Equipment: Smart factories often rely heavily on data centers and IT infrastructure. Many data center components, such as servers and networking equipment, operate on DC power. Switching to DC power at the factory level can streamline the overall power infrastructure.

7. Cost Savings and Total Cost of Ownership: In some cases, the cost of implementing and maintaining DC power systems might be lower over the long term, especially when considering factors like reduced energy consumption and the longevity of DC-powered equipment.

However, it’s important to note that the implementation of a solar-powered DC system in a smart factory requires careful planning, design, and consideration of various factors such as energy demand, storage capacity, and system compatibility. Additionally, the economic viability of such a system depends on factors like local solar conditions, available incentives, and the cost of solar technologies.

Three statistics that support the benefits of DC power systems in industrial applications, particularly when integrated with solar power and in smart factory settings:

- Reduction in Energy Losses: In direct current (DC) systems, line losses can be significantly lower compared to alternating current (AC) systems. For instance, in certain applications, the line loss of a DC system can be about 0.277 times that of an AC system when high-power loads are considered. This demonstrates a substantial reduction in energy losses, which can enhance overall energy efficiency (MDPI).

- Energy Efficiency in Electric Motor-Driven Systems: Electric motor-driven systems (EMDS), which are prevalent in industrial applications, account for over 40% of global electricity consumption. Studies suggest that optimizing these systems could save approximately 25% of their electricity use. This optimization is more feasible with DC systems due to better compatibility with variable speed drives and reduced conversion losses (IEA).

- Data Center Efficiency: In data centers, which are critical components of smart factories, DC power systems can lead to significant efficiency improvements. A typical data center might see overall energy savings of about 10% at the UPS (Uninterruptible Power Supply) level due to reduced power conversion requirements when using a DC system compared to an AC system (MDPI).

Key features of DC when considering green energy/sustainability

- Direct Compatibility with Solar Panels: Solar panels generate direct current (DC) electricity. By using DC power in the factory, you can directly connect solar panels to the power system without the need for inverters to convert DC to alternating current (AC).

- Reduced Energy Losses: Avoiding the conversion between DC and AC can improve overall energy efficiency. Traditional AC-DC-AC conversions result in energy losses, but with a DC-centric system, these losses are minimized.

- Streamlined Power Distribution: Many devices and components in a smart factory, especially electronic equipment, sensors, and actuators, operate on DC power. Using DC throughout the system simplifies power distribution and reduces the need for additional converters.

- Battery Storage Integration: DC systems can be more compatible with battery storage technologies. Excess energy generated by solar panels during peak sunlight hours can be stored in DC batteries for later use, providing a more stable and reliable power supply.

- Enhanced Control and Monitoring: DC power systems can offer better control and monitoring capabilities, allowing for more precise management of power consumption and distribution. This aligns well with the requirements of smart factories that rely on advanced automation and control systems.

- Reduced Electromagnetic Interference: DC systems generally produce less electromagnetic interference compared to AC systems. In a smart factory where sensitive electronic equipment is prevalent, minimizing electromagnetic interference can be crucial for reliable operation.

- Environmental Sustainability: Combining solar power with DC systems contributes to the overall environmental sustainability of the smart factory. It reduces dependence on traditional power sources, lowers carbon emissions, and aligns with corporate sustainability goals.

- Grid Independence: By incorporating solar power and DC systems, smart factories can potentially reduce their dependence on the grid during daylight hours, leading to greater energy independence and potential cost savings

Switching to DC power in smart factories, especially when integrated with solar energy, offers enhanced efficiency, reduced energy losses, and greater sustainability. This shift aligns with global environmental goals, promotes renewable energy use, and supports more precise control and automation in manufacturing processes.

Read more about> Evaluating Progress Of Australia’s Manufacturing Journey Vis-À-Vis Germany