Having produced an ‘artificial heart’ device, Ventracor’s vision is to become the world’s major supplier of cardiac assist systems and to improve the quality of life for people suffering congestive heart failure. So when Ventracor approached Ti2 with a new project, it came as no surprise that it would be more then a simple project. After all, several Ventracor’s engineers had worked with Ti2 before on unique solutions at other Healthcare companies.

Ventracor

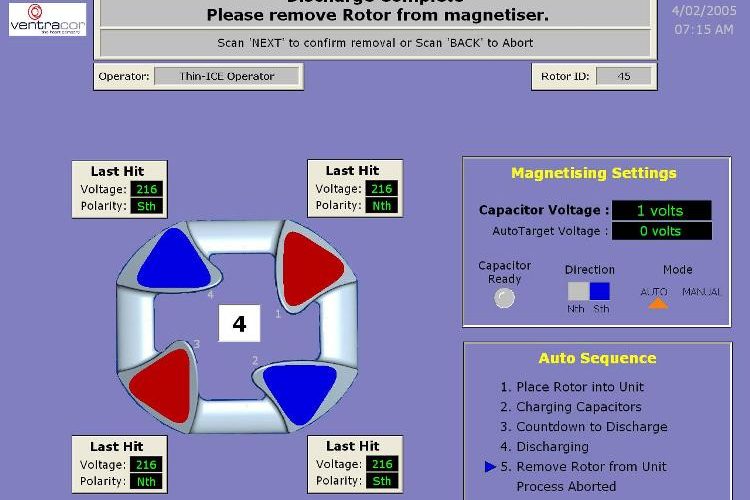

The task was to create a pump rotor magnetising and measuring system, which included the following directives:

- Follow strict clean room requirements

- Track every operator action, including operator ID, data and time of each magnetising and measuring operation, result of each action

- Automatically create reports on the entire rotor magnetising history

Understanding the importance of open technologies, Ventracor also requested that the system conformed to certain standards, including IEC61131-3 programming and OPC connectivity.

The purpose of collecting the data is three fold

- To securely store a complete production history to satisfy FDA and other health regulations

- Provide data to analyse historical quality of rotors supplied to the process

- Use the historical data to improve automation algorithms, and improve efficiency of the process

The final solution makes use of many 4Control strengths

- Multiple program targets PC and EC

- Communication to a number of devices, including bar code scanner and flux meters

- Operator interface

- Database connectivity