Description

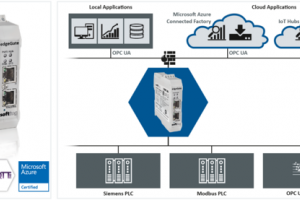

Protocol Conversion for Data Exchange between Multi-Vendor Automation Systems

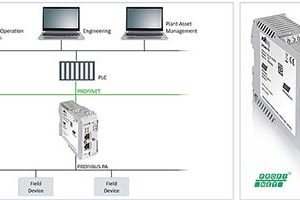

- Integration of robust control technology without having to adjust control software

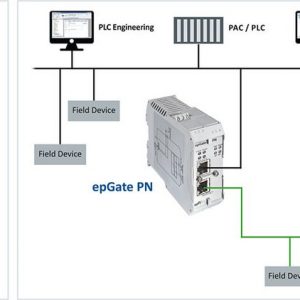

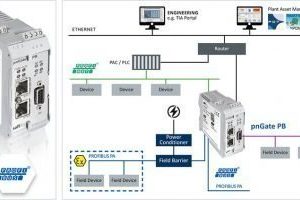

- Combination of separate networks with different media via configured connections

- Connection of physically separate networks with different media or heterogeneous networks with identical medium

- Connection of data from different control systems via allocation tables

- Bi-directional conversion and writing of PLC data via configured connections

- Analysis of device functionality and extensive Ethernet diagnostics

Support of Multiple Industrial Standard Protocols

- Support of TCP, UDP, IP, ISO (H1), ISO on TCP (RFC1006), PLC Header, EtherNet/IP Ethernet protocols

- Linking of computers with TCP/IP to ISO (H1) networks

- Remote maintenance of ISO (H1) networked controllers via TCP/IP

- Routing support for controllers

Investment Protection and IT Maintenance Cost Reduction

- Standard component for extending functionality without modifying existing systems

- Very easy configuration through straight-forward project import without requiring control modifications and programming skills

- Remote configuration and diagnosis via remote maintenance if required

- No need for additional PC with software updates and additional administration

- Working for years once configured – untouched, without updates, and with zero maintenance costs

- Supporting plug-and-go replacement if required based on configuration data stored on SD card