Wind turbines have emerged as a highly efficient and sustainable alternative to traditional power sources. However, like any other power generation system, wind turbines require a high level of monitoring and control to ensure optimal performance and safe operation. One critical component in this regard is the Analogue Input/output (AIO) module, which serves as a vital interface between the physical world and the control system.

In this blog post, we will explore the relevance of AIO modules in wind turbine power generation, their advantages, and their applicability in other energy sectors.

Analogue Input/output Module in Wind Turbine/Power Generation

In a wind turbine power generation system, the AIO module plays a crucial role in monitoring and controlling various parameters such as wind temperature, pressure, voltage, wind direction, wind speed, generator speed and temperature, control yaw and twist, and current. These parameters are essential to ensure the safety and optimal performance of the system.

The AIO module typically consists of two main components: the analogue input module and the analogue output module. The analogue input module is responsible for converting the analogue signals from various sensors into digital signals that can be processed by the control system. Similarly, the analogue output module is responsible for converting digital signals from the control system into analogue signals that can be used to control various actuators and devices.

ODOT Automation offers AIO advantages comprising:

- All metal shell with strong anti-interference ability

- 35mm DIN rail, professional buckle installation, and anti-vibration to ensure stable operation

- Temperature: -40°C – 85°C,

- Compact size, occupying little internal space

Suitable for harsh weather – the use of advanced control system and sensors from AIO can be used to optimise energy extraction and reduce structural loads. For example, Gobi regions, tidal flats, and offshore wind power control systems relies on AIO as advanced sensors to optimise power capture.

Advantages of Using an AIO Module in Energy Plants

There are several advantages of using an AIO module in energy plants, aside for wind turbines. Firstly, AIO modules provide a high level of accuracy and precision in measuring and controlling various parameters.

When capturing power and extracting energy from wind turbines, several types of data must be measured and controlled. These include:

1. Wind speed: The anemometer measures wind speed, which is critical in determining the amount of energy that can be extracted from the wind.

2. Blade angle: The pitch system adjusts the blade angle to control the rotor speed and energy output.

3. Rotor speed: The rotational speed of the rotor is important for power and efficiency.

4. Generator output: The generator converts the mechanical energy from the rotor into electrical energy, which is measured and controlled.

5. Torque: The torque control of the generator allows varying the speed of the turbine rotor to achieve maximal extraction of energy.

6. Structural health: The operating limits of the cut-in and cut-out speeds must be monitored to maintain the structural health of the wind turbine.

By measuring and controlling these parameters, wind power plants can optimise energy extraction and reduce structural loads, resulting in increased efficiency and reliability of the wind turbines.

The AIO modules offer high accuracy, scalability, flexibility, and cost-effectiveness with configurable modules for overload and short circuit protection, as well as galvanic isolation, allowing reliability and durability in harsh environments.

This is critical in ensuring the safety and optimal performance of the system since the components generate a significant amount of heat and are subject to high winds and vibrations. Finally, AIO modules are highly flexible and can be easily integrated into existing control systems, making them an ideal choice for retrofitting and upgrading existing power generation systems.

Applicability of AIO Modules in Other Energy Sectors

AIO modules are not limited to wind turbine power generation systems and can be used in other energy sectors such as solar and gas. In solar power generation systems, AIO modules can be used to monitor and control various parameters such as solar radiation, temperature, and voltage. Similarly, in gas power generation systems, AIO modules can be used to monitor and control various parameters such as gas pressure, temperature, and flow rate. In both cases, AIO modules provide a high level of accuracy, reliability, and flexibility, making them an ideal choice for monitoring and controlling various parameters.

In Australia, AIO modules have been widely used in wind turbines to monitor and control various parameters.

Ti2 Pty Ltd is the official distributor for ODOT in Australia, offering automation products with expertise from world-class suppliers. We provide robust competitive industrial automation solutions helping manufacturing companies among other emerging industries.

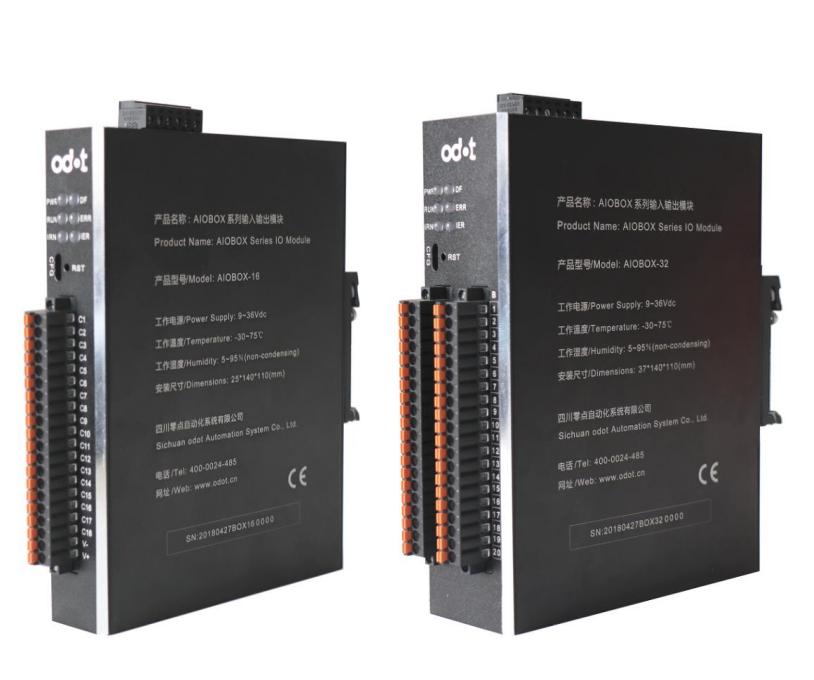

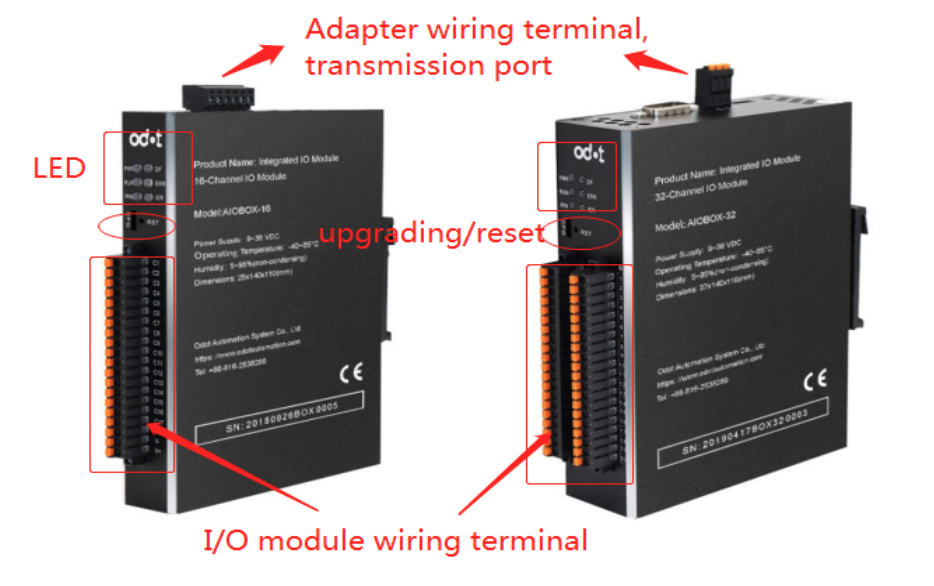

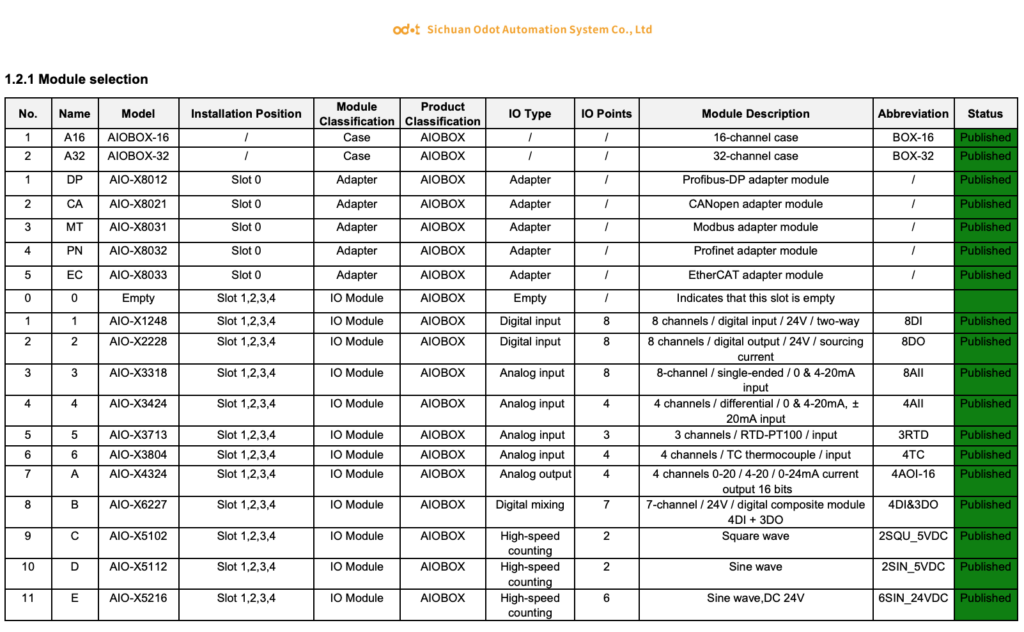

ODOT Automation AIO Box Series offer a complete range of modules for various applications.

View the following brochure to learn more about ODOT’s AIO Box Series.

ODOT Automation – AIO Box Series

To learn more about what we do and how we can help your interoperability requirements, please click projects, products & services.

Ti2 is currently very focused on working with its global partners to secure stock and avoid long delay times in delivering products to their customers. Together with our trusted partners, we are here to provide solutions.

Please click here to email us your inquiry, we would like to hear from you.