Quality Assurance (QA) data controls how products are made, and the repeatability in production that is vital in all pan-industrial manufacturing scenarios which makes QA to become a fundamental digital task that offers facilities efficient and cost-effective production processes. With this the QA drives Industry 4.0 where the non-contact 3D optical metrology solutions has grown in the recent years as the Industry 4.0 processes easily fit the image processing and vision systems.

Metrology was once serves to catch failures within a production process but today it has become the source of bucket loads of data that can be used to fuel the systems in a smart factory or Industry 4.0 environment, and promote true data-driven production.

Drilling into Industry 4.0

Efficient production has become the key driver for manufacturers which makes the Industry 4.0 solutions to gain traction across all key industrial sectors since using a digital technologies can stimulated innovation and improves production processes. Industry 4.0 will become much more important as these technologies continues to enhance and become less expensive.

Competitive model and focusing of increasing the capacity to deliver a more cost-effective products through the digitization of the entire production process is the requirements for the Industry 4.0 concept. But today the businesses has completely re-assess their value chains, and try out different ways of thinking and toolsets, fusing the physical, digital, and virtual worlds together. The integration of the intelligent productions systems and advanced information technologies, the fundamental of the foundations and future of many world’s leading manufacturers was encouraged by the Industry 4.0.

The Power of Metrology Driven Data

Industry 4.0 uses data key, upstream and downstream in the product development process, with the algorithms adjusting the manufacturing process that ensures consistency, efficiency, and the repeatable production with zero failure rates. A fast non-contact optical metrology systems is used in 3D data capture that is directly fed to the quality control team who analyse its conformance with design intent by comparing it with the 3D CAD solid models.

With this automatic process the overall efficiency and cost-effectiveness of the production were enhanced and it reduces failure rates and scrap. The quality, quantity, and speed are being enhanced by the 3D optical metrology solution in which the data is collected.

Smart Factory Metrology Solutions

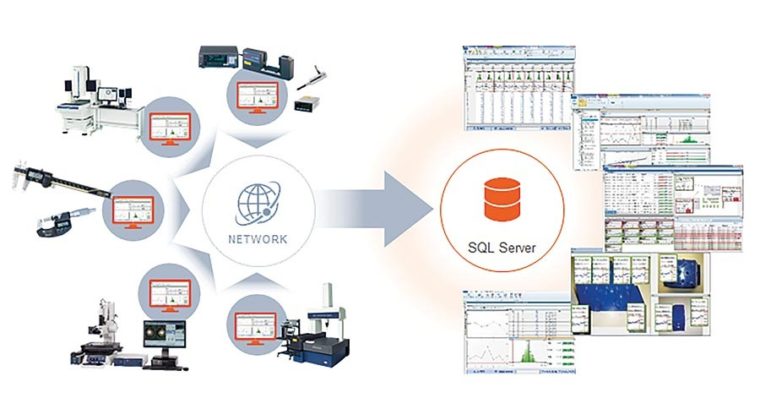

Collecting ad sharing data through inter-connected devices, machines, and production processes is the role of metrology in the digitized factories for it to support digital production at every stage. The small factories goal is for the manufacturers to evolve their processes in order for them to close the gaps in inspection-related data at every stage in the production value map and giving the manufacturers to have a greater visibility of the entire supply chain which includes the suppliers.

Shifting the key driver from in-lab to in-process is a desire to acquire a “faster time to data”, and the ability to make decisions as a result of that data faster which makes it the key element for Industry 4.0 and the efficient running for a smart factory. IN-process solutions has a number of advantages, speed is on of them in which the data derived from it can influence the decision making. In in-lab the parts must be move to the QC department and then set up for the metrology operation to be undertaken. Various process steps are removed in the in-line metrology, defects and problems can be identified and reworking is reduced. While in the in-process metrology it prevents the problems before they arise and if they manage to arise it allows them to be identified and addressed them before they become a costly and time consuming issue.

Industry 4.0 concept is fit with non-contact optical metrology solutions since they are speedier and can cover larger areas than contact devices. While integrating 3D optical metrology promotes automated closed-loop production which improves the computer processing and optical technology which makes the acquired amount of data and analysed is vastly increased. Allowing the processed data to be fed from the metrology system into the factory management system is the 3D optical metrology solutions were used in the in-process and it also advances the smart factory concept.

Please contact us for further information.