Food & Beverage Manufacturing & Processing Automation: New Turn-Key Solution In Motion Control With CMZ for Industry 4.0

Food and beverage processing requires agility in automation to stay on top of market demand. Moreover, with the pandemic occurrence, the industry has transformed and accelerated in terms of machinery automation.

CMZ Sistemi Elettronici Sri is a leading Italian producer of solutions for the industry since 1976, specializing, among others, in industrial motion control. Our partnership with CMZ has strongly reduced the time to market for new packaging and beverage machines by developing and realizing hardware and software systems.

As each product and processing require a different system and infrastructure, CMZ and Ti2 understand this and together provide you with a fully customized and integrated configuration required.

Ranging across hardware and software components (controllers, brushless and stepless Servo Drives and Motors, Libraries, Apps, up to Hmi operator panels) CMZ build up a whole customized electronic system for the motion of vertical and horizontal flowpacks, multihead and linear weighers, filling and bottling machines, capping and labelling machines, loading systems, end line.

30 years of outstanding know-how and deep experience have helped CMZ state-of-art technologies to be fully in accordance with OEMs and system integrators to easily facilitate the dynamics of the machine and the need for cost reduction.

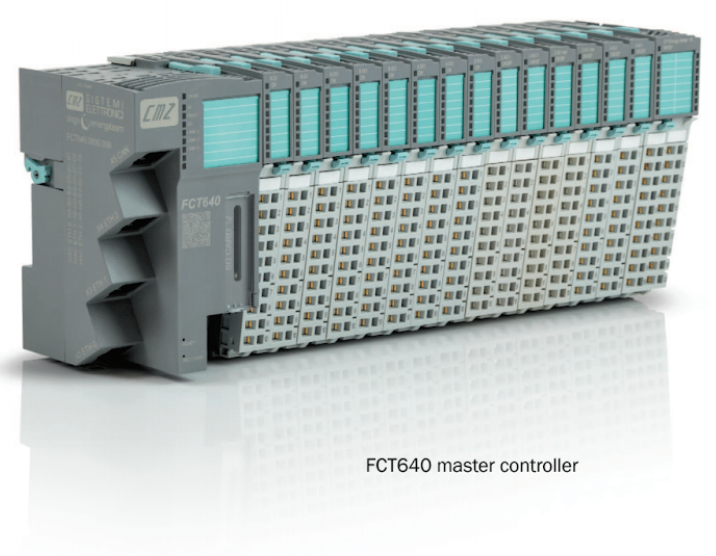

CMZ has recently introduced powerful custom libraries IEC 61131-3 for flowpacks. Using the newest controller FCT640 with Codesys c3.5 and CMZ motion libraries, every machine can be ready to pack any format depending on the manufacturing needs.

Software Features

Based on the international standards requirements, CMZ software features:

- Multilanguage interface

- Unique configurable software for all size solutions (no need to upgrade)

- Dynamic mapping of HW directly on the HMI

- All parameters set up according to the access privilege

- 100 recipes on SD card removable

- Full Diagnostic

- Updating software easily by SD card.

Hardware Features

Meanwhile, CMZ hardware solutions range from the most cost-efficient to the most compact and dynamic in terms of Motion:

- Stepless Standard: SVM drive with Motor Encoder Box

- Stepless Integrated: ISD (Integrated Stepless Drive)

- Brushless Standard: LBD drive with Brushless motor

- Brushless Integrated: IBD (Integrated Brushless Drive

Pharmaceutical – Motion Control for Aseptic Processing – Filling Machine XI SERIES

CMZ extends its motion control solutions to the pharmaceutical industry ensuring safety, precision, and speed. CMZ FCT300 controller has the hardware intelligence built to be the perfect balance between power, flexibility, programming versatility, and price. As a perfect combination, CODESYS developing environment and the IEC61131 programming standard make this system an open solution for quick, real-time communication between devices. Finally, with this excellent system, software development times are drastically reduced, allowing the reuse of part of the code for future applications.

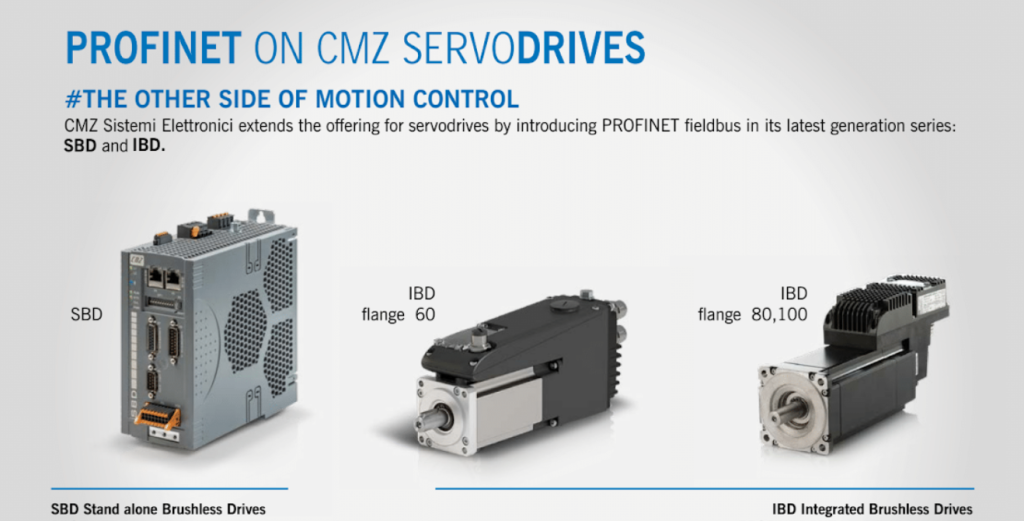

PROFINET on CMZ SERVODRIVES

On the other side of motion control, CMZ also offers servo drives by introducing PROFINET fieldbus in its latest generation series: SBD and IBD.

PROFINET is available in all sizes and available on motors with flanges 60, 80, and 100 mm.

This open Fieldbus is based on Ethernet, providing:

- General Ethernet Services

- Fieldbus services:

- Cyclic data (similar to PDO in CANopen)

- Acyclic data (similar to SDO in CANopen)

- Diagnostics messages (similar to Emergency in CANopen).

CMZ PROFINET DRIVES SOLUTION

- Not isochronous real-time cyclic data exchange (RT)

- Application Class 3 functionality for axes “command mode”

- The servo drives PNT of CMZ can be used in IRT networks

- Custom telegrams and PROFIdrive vocabulary

- HW architecture based on chip HMS.

In addition to CMZ typical functionalities, PROFINET also provides an interface with SD-setup and an integrated PLC.

CMZ servo drives SBD and IBD can be used in a PROFINET network and be recognized and controlled by Siemens controllers (or any other PROFINET controller) thanks to the GSDML descriptor file.

CMZ SBD drives, defined in class 3 (RT), can be used also in networks with devices of superior class (IRT).

CMZ has implemented both the cyclic communication (for the servo drives management) and the acyclic communication (for access to the PROFIdrive vocabulary).

To learn more about what we do in partnership with CMZ and how we can help your process automation requirements, please click projects, products & services.

Ti2 is currently very focused on working with its global partners to secure stock and avoid long delay times in delivering products to their customers. Together with our trusted partners, we are here to provide solutions for your needs.

Please click here to email us your inquiry, we would like to hear from you.

Article inspired from CMZ.