The rise of IOT in the warehousing and logistics Industry

The IOT (Internet of Things) is being used in all industries as part of Industry 4.0 and it’s adoption is continuing to expand. IOT refers to a network of connected smart devices extracting information from which businesses can get useful insights. With the increase of resources and available data, businesses will be able to optimize a wider range of operations, minimizing costs and improving profitability.

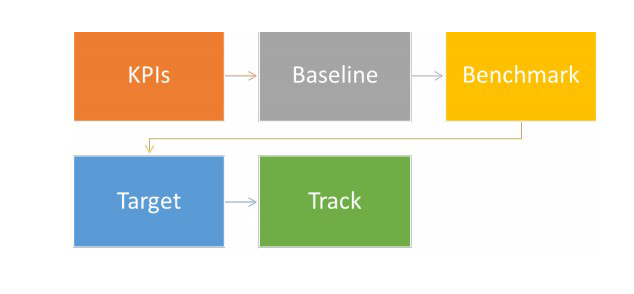

Steps to using IOT to measure efficiency goals for warehousing plants:

In the following section, shows how the use of IOT can set measurable efficiency goals for warehouse loading docks.

- Choose your KPIs

For this guide the KPIs that we recommend you use for your loading docks are: productivity, utilization and dock turns.

- Record a baseline

For you to know if the performance improves you need to set a baseline for your current operations. i.e. how are you performing today? With the variation in anything, using a single data point is not a baseline. It needs to have several data points and should reflect the environment you are setting as a target in order for the baseline to effective. Collecting data for 1 month to set your baseline would allow your baseline to cover all aspects of your loading dock operations that would give you enough data to average out the variations in dock performance and highlight outliers.

- Find a benchmark

Baseline data gives an understanding on the site performance and then, using benchmarking, we can compare the levels of performance from one dock to another. A benefit of using IOT, will be the volume of data that will be accessible however, one must define benchmarks that would affect target KPIs.

- Set and agree tailored targets

It is important to tailor targets to situations, if you don’t this can result in unrealistic expectations being set and efforts being focused on minimal impact aspects of your operations. Use your benchmarks to set realistic targets.

- Make changes and track results

Without IOT you would have zero visibility on your progress to achieving your targets unless you organized another manual audit which would only give a snapshot in time. With IOT you and the supervisors responsible for your loading docks can have complete visibility and transparency on loading dock performance. This continuous stream of data makes it easy to see the impact of your changes, showing you when you are doing a good job and when you are off track.

Inspired content from Castell.com

For more information please do contact us.