If we rewind a few decades back, we’ll see that the Direct Digital Control or DDC system is the predecessor of DCS and PLC. Stepping forward, local I/O in PLC is the most basic system that we use. Contained within one cabinet body, and in-built I/O’s in the CPU assembly. Local I/O is known to be beneficial for PLC systems that are limited to a certain distance, especially near the electrical panel. It’s still possible to connect them to the PLC, however, the risk of signal drops may be significantly high, which could mess up your system wiring.

Another step forward and you have Remote I/O in PLC. ‘Control system’ became architecture and communication, art and science.

This was when PLC started to make sense. If local I/O was compared as one man in a cabin, now we have technical staff across the room. Separate, independent, but under control. This solution was known for its distance flexibility compared to the local I/O.

Increased rate and speed of data transfer as well as reduced data to minuscule sizes are now important objectives.

With remote I/O, refineries and plants became less risky and more possible. Comprising sets of I/Os, remote racks connect each cluster, even those distant, through a network adapter. This communication module allows any available protocol such as Ethernet IP, Modbus TCPIP, Profibus, Profinet, etc.

Although many claims that remote and distributed I/O are extremely similar, the distributor I/O is considerably a more advanced system where the DSC has multiple ‘brains’ or so we call a number of distributed autonomous controllers.

Each of which is a control system that operates each designated parameter, connected together through a centralized supervisory controller. CPU is present within each remote rack to prevent strain in the increase of overall memory in the main PLC as well preventing a lengthy program.

Local VS. Remote I/O

Understanding the difference between local and remote I/O modules will give you a good comparison to choose from depending on the feasibility of the situation.

To briefly explain:

- Local I/O is a subsystem that is housed within the same cabinet or rack as the controller. Due to its proximity to the controller, a local I/O wouldn’t have any computing power.

- Remote I/O, also known as Distributed I/O, is usually located separately, or ‘remotely’ from the main controller. The distance allows this module to have some level of computing power. You can perform data processing and outputs switch independently from the main processor.

In conclusion:

- Remote I/O within the main cabinet will allow benefits such as safety, less wiring, and standardization.

- Remote I/O is fairly cost-efficient, although depends on the existing network infrastructure.

- Wireless remote I/O may also be beneficial (engineers are often skeptical about wireless dependability), but remote I/O will help with real-time data collected.

With an existing control panel, you can simply add a wireless I/O to collect data such as vibration or temperature in the panel. – There’s no need to build a whole new infrastructure.

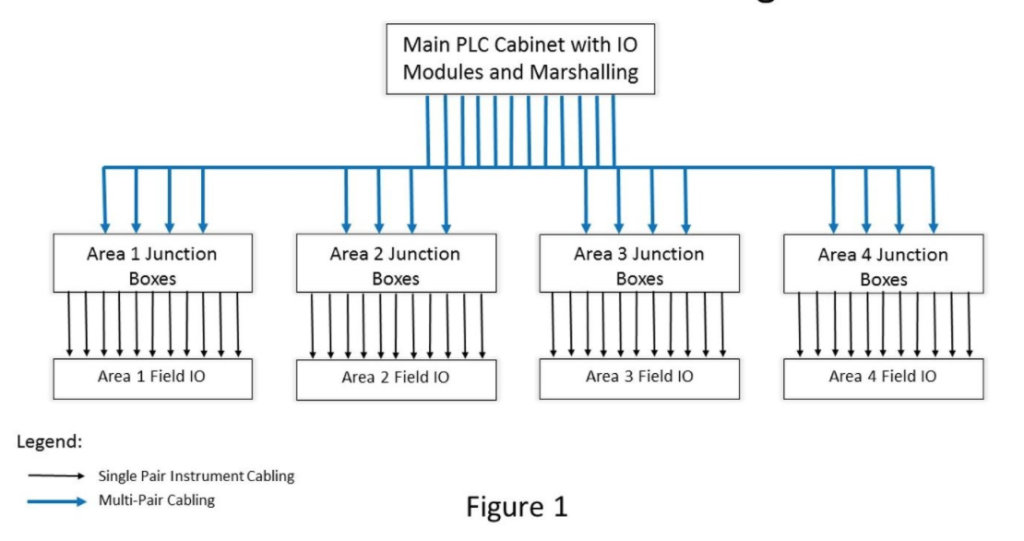

Traditional Junction Box Design

A traditional Junction Box Design serves as a typical implementation for large industrial facilities with several junction boxes (locations). Junction boxes are usually distributed throughout the facility, wired with individual cables.

The junction box is a splice point to allow for larger multi-pair or multi-conductor (home run) cables to connect back to the main PLC.

This method enables each cable to run to an end device with at least 4 terminations (PLC, multi-conductor side, field side, and end device.) This equates to at least two added failure points or possible errors for each and every conductor.

Compared to a traditional Junction Box Design, a remote I/O with modern PLC can have multiple single points of failure, which builds redundancy in the communication system and at a high percentage, removes the potential of single-point failure.

With a remote I/O, even if any main (red) cables were to be cut, data loss is preventable due to the redundant ring type of network. No more long-distance cable installation, with remote I/O, two small communications are enough, no matter the size of the expansion.

Although remote I/O may require a higher cost in the start due to additional networking components such as Ethernet, fiber cards, patch panels, and switches; implementation cost will significantly decrease, saving up around 30-50% of the cost. The risk of slow-speed, fault, and drawbacks are completely gone with a remote I/O, in addition to the flexibility and overall cost-saving solution, remote I/O is considered the number one I/O system for industrial automation.

As further Innovations such as with Siemen’s bus adapters, removable modules that plug into remote I/O interfaces, higher bandwidths that can be updated through a firmware change, thereby providing protection against demands for increased bandwidth that may arise over time. Also, avoiding damaging ports with constant cable connecting but with easier solutions for defective ports to be replaced without labour intensive or costly interface replacements.

Also, since the remote I/O is much more intuitive it lessens the burden on a central controller, helping solving problems, easier to scale and minimizes single points of failure.

So, to conclude Remote I/O module technology provides access to sensor-level data in difficult to reach areas. This ensures smoother operation of system components while streamlining device replacement and machine maintenance – again saving costs and improving efficiency offering:

– Simplified Configuration and Monitoring

– Efficient Device Replacement

– Enhanced Diagnostics

Ti2 is currently very focused on working with its global partners to secure stock and avoid long delay times in delivering products to their customers. Together with our trusted partners, we are here to provide solutions.

To learn more about what we do, please click projects, products & services.

Please click here to email us your enquiry, we would like to hear from you.

Article inspired from automationworld, hm-ec decisions, and realpars.