The gap between the industrial equipment and automation networks also known as the Operations Technology (OT) and the Information Technology (IT) were being connected through the Industrial IoT (IIoT). Machine learning, cloud, mobile, and edge computing are new technologies that has become commonly used in the IT. To improve the performance, productivity, and efficiency of the industrial processes the IIoT brings together the machines, cloud computing, analytics, and people that would enables the customer to turn to IIoT applications which could help them to remotely monitor, operate, and maintain the machines from anywhere.

These are the three elements of IIoT that are holding manufacturers back:

- Data is collected too infrequently

- Data is difficult to access

- Unable to overcome data silos and link data together

The usage of Predictive Quality of the industrial companies will be discuss which would improve the quality of factory output by determining the adjusting machines settings, using different sources of raw material, or doing additional worker training.

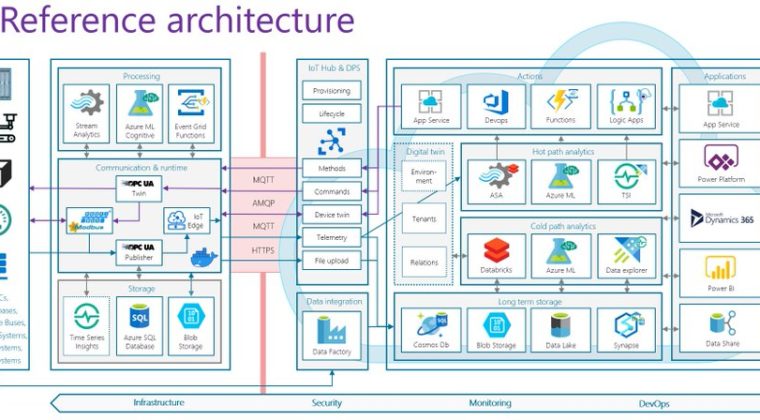

The following picture shows the ISA-95 Industrial Edge Architecture and how the above-mentioned elements are related to each other.

Current situation and challenges of the Industry

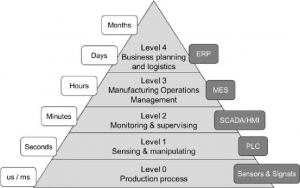

Most equipment/machines usually have 10, 20 or even 30 years to work efficiently whether your in he manufacturing, utilities, oil and gas, or other industrial market segment. Since Operational Technologies were designed to be used for a couple of decades and are very difficult to replace most of these companies uses Operational Technologies such as Industrial PCs (IPCs), Programmable Logic Controllers (PLCs) or large Distributed Control Systems (DCS) with real-time distributed control networks (fieldbuses) connecting them, and Supervisory Control and Data Acquisition (SCADA) systems.

Adapting to the existing equipment and systems that is not designed for IoT application could help us in benefiting from the new technologies such as IoT, machine learning, and computer vision.

Connecting the legacy equipment to any IIoT application will be the first hurdle to face in order for the company to collect data from different devices from different manufacturers.

The second after connectivity is the most important which is the security. During the equipment or system failure a costly downtime could impact the business. The company must ensure that the connected devices could operate even without cloud connectivity. Collecting data processes should not interfere with the device operation and any remote control or update operation so that only allowed operators can have access.

After securing the data the last challenge would getting the insights. Getting the insights in all raw data the data must be link together even if the data comes from a different devices, manufacturers, historians, fieldbus, systems or databases since data is locked in different “floors” of the factory.

How it works

IoT lets the industrial companies to easily connect, manage, and update devices from any devices and can integrate the existing legacy of the company on the manufacturing floor such as Programmable Logic Controllers (PLC) and Supervisory Control and Data Acquisition (SCADA) systems through a sensor that could monitor processes and tracked performance indicators without replacing the existing hardware.

To keep the IoT data and devices protected a built-n device authentication is provided. Security policies on the devices can be audit continuously, monitoring the abnormal behaviour of the devices, and receiving alerts if something is out of place.

Operating with intermittent Internet connectivity through connected devices were enable by IoT in order to prevent risk of unexpected downtime.

A “plug and play” is provided by IoT for easy use. Devices can be manage and monitor remotely across any location which include updating device software over-the-air (OTA).

The following are the most important industrial use cases in the IoT services:

- Asset Condition Monitoring

- Predictive Maintenance

- Predictive Quality

Sources for content & feature image: AWS Amazon Blog on IoT & TweetDeck

Contact us for further information