Within the major scopes of I/O module functions, ODOT’s integrated I/O module covers it all from processor and device communication, data buffering, control, timing, as well as error detection. ODOT’s B Series integrated I/O modules are practical to incorporate with many peripherals and diverse sets of logic within the processor. With fast data transfer and convertible communication protocols, this I/O module can manage, store, and communicate with peripherals towards various I/O sources.

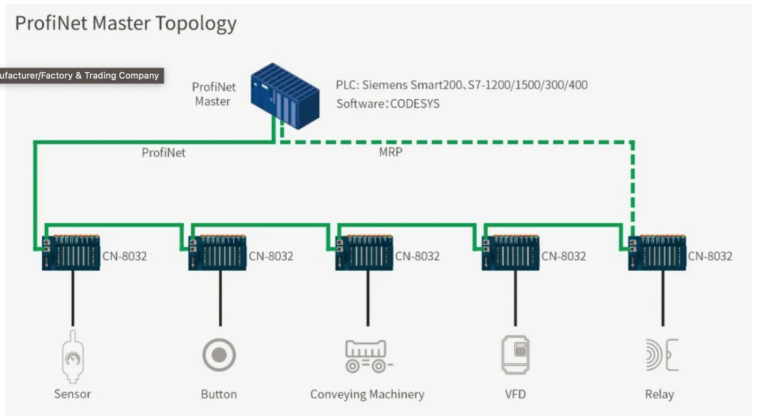

ODOT’s B series integrated I/O module consists of a communication board (COMM board) module and an extended IO module. The COMM board could select the corresponding bus module according to the communication interface of the controller system. The mainstream industrial communication protocols include Modbus, Profibus-DP, Profinet, EtherCAT, EtherNet/IP, CANopen, CC-Link, PowerLink, etc. The extended I/O module is divided into six categories: digital input module, digital output module, analog input module, analog output module, special module, and hybrid I/O module.

The COMM board and extended I/O modules could be freely combined based on site requirements. The integrated I/O module could lower the cost when there are few data points.

Succinctly, the integrated I/O module will help the different communication protocol issues that many peripherals face and prevent processors from converting back and forth.

ODOT’s B Series integrated I/O module can be implemented across various industry applications such as:

- Machinery Industry

- CNC

- Food and beverage

- Smart factory

- Automotive

- Energy Industry

- Thermal plant

- Wind plant

- PTD

- Solar plant

- Process Control Industry

- Hydropower station

- Oil and Gas plant

- Chemical plant

- Others

- Railway/Urban

- Building

- HVAC/Construction

ODOT B series is an integrated I/O module with modular combinations inside. The power supply and COMM board are at the bottom, and the IO module communicates with the COMM board through the backplane (the green module as below). It could support an expansion max of 4 IO slots (only 2 IO slots are installed in the below diagram).

Together with CODESYS, our trusted automation software partner, ODOT automation’s purpose is to offer a great price, and premium quality, compatible with CODESYS PLC, as well as many other golden companies. With the quality comes the guarantee, if you’re not satisfied with your product quality, you can return the product within 7 days.*

Size:

With over 40 partners and major companies as customers, ODOT strives for excellence, with constant improvement and innovation. They’re committed to establishing customer trust and becoming a first choice for their partners.

Founded in 2003, ODOT Automation System Co., Ltd, is a technical enterprise specialising in industrial communication and automation control system R&D and integrated technical service with 18 years of experience in industrial communication products, especially on I/O system solutions.

With over 1500 sqm factory and an independent technical development center with professional engineering and IT team, ODOT has established a strong presence, not only in South East Asia but all around the world, boosting smart factories systems and pioneering IIOT as a mission.

Ti2 Pty Ltd is the official distributor for ODOT in Australia, offering automation products with expertise from world-class suppliers. We provide robust competitive industrial automation solutions helping manufacturing companies among other emerging industries.

To learn more about what we do and how we can help your interoperability requirements, please click projects, products & services.

Ti2 is currently very focused on working with its global partners to secure stock and avoid long delay times in delivering products to their customers. Together with our trusted partners, we are here to provide solutions.

Please click here to email us your inquiry, we would like to hear from you.