The digitization of field devices in the process industry, the growing importance of predictive maintenance and the increasing possibilities offered by centralized field device configuration in modern asset management systems have all paved the way for the expanded use of digital communication protocols like fieldbus and HART. At the same time, WirelessHART has become established worldwide as the leading wireless protocol for process applications. When implementing WirelessHART gateways or when adding HART multiplexers to an existing infrastructure, HART-IP provides a new standard protocol ensuring efficient integration. HART-IP also enables easy integration of HART data into asset management applications.

HART-IP enables end-to-end device communication

As diagnostic data become more important and field devices in process plants more digitized, an ever increasing number of users and system providers are moving their focus to HART-IP. It enables complete plant-wide, large-scale solutions and offers a high degree of interoperability between devices and applications. The protocol runs over IP-based networks such as Ethernet and Wi-Fi and works over UDP (User Datagram Protocol) and TCP (Transmission Control Protocol) with IPv4 (Internet Protocol Version 4) or IPv6. The HART-IP application layer is based on the same commands as 4-20 mA/HART and WirelessHART.

In contrast to serial data transmission, process and IT data can be transmitted over a common medium. There is a large address space with an almost unlimited number of participants available, and cascading switches enables the creation of huge networks. Furthermore, larger amounts of data can be transferred efficiently and different transmission media (copper, optical fiber, radio) can be combined.

HART-IP is a high-level application protocol independent of the underlying media and works over standard Ethernet (IEEE 802.3), both copper and fiber, as well as Wi-Fi (IEEE 802.11) equipment. It is thus suitable for use with standard infrastructure components like LAN switches, routers, access points, cables and connectors. HART-IP can also utilize existing network structures with redundant Ethernet media as well as mesh or ring topologies, or Power over Ethernet (PoE). Various speeds like 10 Mbit/s, 100 Mbit/s and 1 Gbit/s are supported.

Using IP-based communication enables multiple protocols to share the same network, each protocol with a specific application. As a result, HART-IP coexists with IT protocols and other industrial Ethernet protocols such as HTTP, Ethernet/IP or PROFINET. There is no need for dedicated infrastructure. The use of multiple clients and servers is also supported, enabling multiple controllers and software applications to access the

data in one or more gateways or multiplexers over the same network.

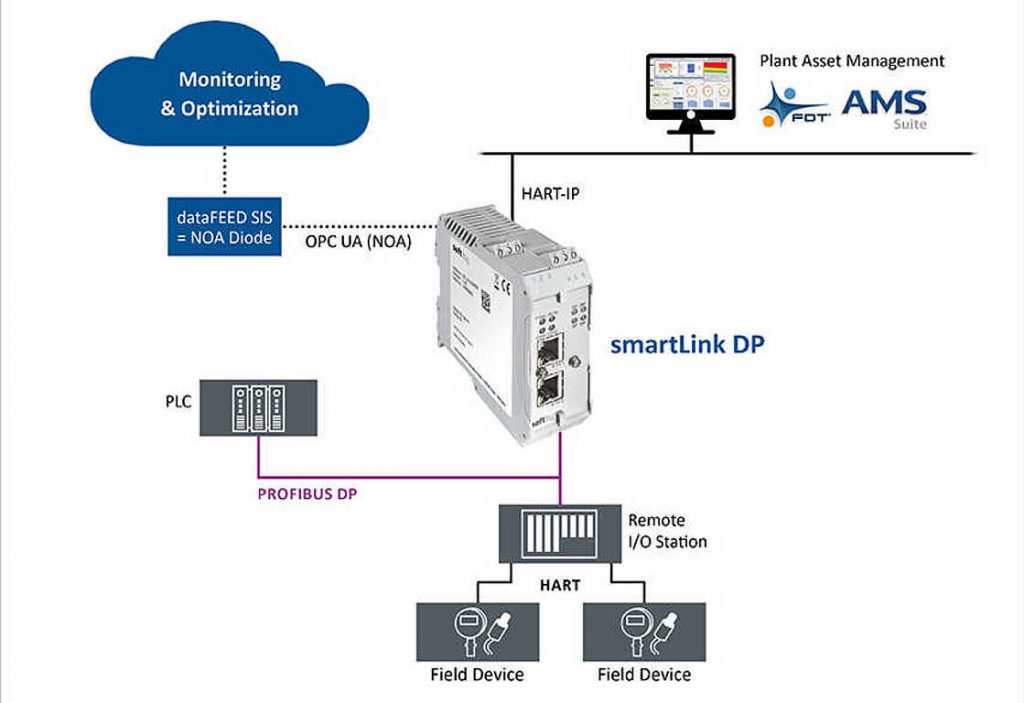

HART-IP can be employed for devices using Ethernet and for HART-IP backhaul networks in HART multiplexers. It is used in Intelligent Device Management (IDM) software as part of asset management systems as well as in OPC servers to access data in 4-20 mA/HART field devices. Specialized applications 2/4 such as software for monitoring steam traps or machinery health already use HART-IP to access device data.

In the future, control systems and automation solutions are expected to provide HART pass-through over HART-IP. HART-IP devices for seamless vertical integration in plants are also conceivable. Some devices, such as flowmeters, already support Ethernet. However, many devices in process plants, such as transmitters, analyzers or valves do not have Ethernet connectivity – nor will they in the foreseeable future. These devices will probably continue to use 4-20 mA/HART, fieldbus or WirelessHART. HART-IP is not yet ready to replace these protocols at the device level, and so far would not be suitable for many reasons:

- The reach of copper Ethernet is too limited.

- Fiber optic Ethernet provides no power.

- Power over Ethernet (PoE) so far is not intrinsically safe.

- Given that there are thousands of transmitters and valves in a plant, the large number of LAN switches to

be installed would not make sense economically. - Fiber optic Ethernet makes device replacement and subsequent calibration impractical.

- TCP/IP requires IT departments to be involved to ensure cybersecurity.

Advanced Physical Layer paving the way for Ethernet in process plants

With the breakthrough of Ethernet Advanced Physical Layer (APL) expected in the next few years, however, the niche existence of Ethernet at field level could come to an end. Instead, the technology could find widespread application as 4-20 mA could be replaced by purely digital 2-wire Ethernet APL (Advanced Physical Layer). APL is Single Pair Ethernet (SPE) and circumnavigates the limitations of 4-20 mA. APL describes a physical layer for Ethernet communication technology that was specifically designed to meet the requirements of the process industry. Ethernet APL was developed because of the need for high-speed, long-distance communication, the need to provide power and communication signals over a single 2-wire cable, and the need to ensure safe operation within potentially explosive environments.

As part of the widely used Ethernet standard, which was developed specifically for sophisticated industrial applications, Ethernet APL offers a high level of robustness for extremely reliable operation. Ethernet has long been established as the standard communication solution in the information technology domain. Industrial Ethernet is the common name for the variant of this standard used in the manufacturing and process industry. Ethernet APL was developed to provide the previously missing link. It extends unified Ethernet communication all the way to field instrumentation, paving the way for the use of communication protocols such as HART-IP, Ethernet/IP and Profinet.

HART-IP is expected to be predominantly used within the plant perimeter. If the protocol is used beyond the plant perimeter via an Internet connection or Wi-Fi, security measures must be employed to protect the data during transport (such as firewalls, VPN tunneling, Secure Socket Layer (SSL), and remote authentication). The standard encryption protocols will continue to evolve and HART-IP is designed to be able to adapt to new versions.

More to come on this topic on Friday 4th Feb 2021… covering Namur Open Architecture, Hart-IP I4.0 applications.

Can’t wait want to know more, please do contact us for further information or sign up for our newsletter.