Motion Control is a key development in the industrial automation market, and moreover in the manufacturing industry. Across the value supply chain, motion control can affect and impact various operations through machines, avoiding countless human errors, speeding up production efficiency, and moreover, effectiveness.

In manufacturing, motion control is known to be a process when moving machinery uses rotary and linear actuators. This sub-field of automation is controlled using a motion-control device. It may range from actuators, electric motors, hydraulic pumps, or servo motors.

As engineers, we are aware that the primary purpose of a motion controller is to control the motion devices dynamically. By signaling and executing commands, motion controllers will power triggers to move the motors or any mechanical devices that are required in the process of assembly lines, machines, robotic devices, etc.

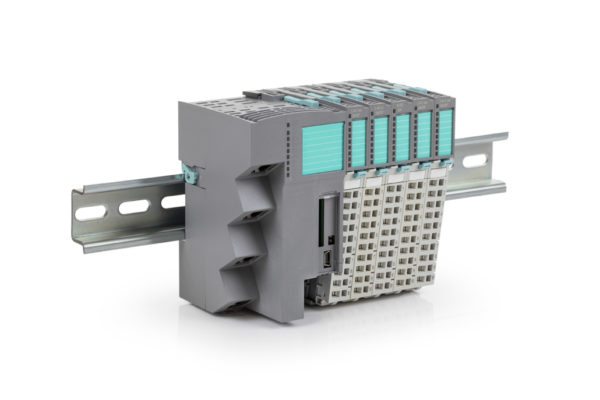

The most widely-used controller in automation and manufacturing applications is a PLC or programmable logic controller.

PLC and motion controller, although at a glance, seems similar, are actually different. Generally, a motion controller uses C or C++ programming language to implement more complex control functions, has an open architecture, and can easily interoperate with multiple devices, systems, and networks.

Meanwhile, there are 3 types of PLC. Based on the output, there are Relay output, Transistor output, and Triac output PLC.

PLC and PAC (motion controller) differ in their architecture and capability between two computers. PLC is still more commonly utilised, with its popular market share of Siemens Simatic PLC, Rockwell Automation Allen Bradley PLC, Mitsubishi Melsec PLC, Schneider Modicon PLC, and the Omron Sysmac PLC.

PLCs vary and range from small modular devices to large rack-mounted modular devices. Smaller range devices can usually facilitate 2-digits inputs and outputs (I/O) while larger scale devices are usually complemented with thousands of I/Os, often it works with networks of other PLC and/or SCADA systems.

The basic advantages of using a PLC-Based control system are as follows:

- Better reliability due to the absence of moving parts

- More flexible

- Little maintenance

- Lower cost

- Easy communication

- Simple troubleshooting

- Faster response time

- Built-in error diagnostics

- Low power consumptions

- Easy to change the logic

- Easy documentation

- Analog signal handling and close loop control programming

- Counter, time, and comparator can be programmed

- Easy operator interface

As it controls the system, it’s also important to have good means of communication with I/O devices such as Fieldbus to ensure smooth integrations. A Fieldbus will reduce cost in the overall system as it speaks to the input devices such as sensors and switches, while also channeling to the output devices such as valves, drives, indication lamps, etc., while ultimately connecting each individual device back to the PLC/controller.

In the beginning, PLCs were built to help the automobile manufacturing industry to replace hard-wired relay logic systems, but after decades of development and improvements, PLCs are not widely known and utilised as high-reliability automation controllers. In addition, PLC is identified as a suitable controller in harsh or rigorous environments.

With a PLC a hard output real-time system is created to increase productivity response with limited time for input conditions. This is key to keeping the timeframe and production KPIs of the operation.

Today, PLCs, PACs, and cloud-based SCADA systems are trends that are significantly influencing the market. The industrial automation control market has resulted in an 8% compound annual growth rate in Asia-Pacific and is forecasted to grow globally over the next couple of years. The unparalleled productivity influenced by high energy efficiency, superior design, optimum safety standards, and better operation visualisation is indeed above all that has been done in the market.

The scope of PLC programming is continuously growing with greater programming flexibility, memory, smaller size, and higher GB speed, with Ethernet and built-in wireless features through USB technology application which makes online programming and remote monitoring easier.

PLCs can now monitor and control multi-user applications/distributed servers as well, providing accurate supervision of operations, and different objectives based on multiple stakeholders’ demands, maintenance, engineering, operations, and production IT.

In the olden days, we connected wires in panel wiring in the relay-based control system, but today, this wiring job is tedious and unnecessary. When an error is diagnosed, troubleshooting the circuit is difficult and relay-based. A quote says‘ Five hours to find it and five minutes to fix it.’ I truly agree.

With PLC, wiring and troubleshooting are easier with CPU for programming. Uploading and downloading the required login is much preferable compared to the relay-based control system.

In addition, in PLC, changing hardware or wiring can be replaced by logic changes inside the controller with IO ports, simply connect the input and output components and write the logic application accordingly. Then download the program using the PLC software.

A one-time PLC purchase is like a lifetime investment. You save a lot of money in troubleshooting, engineers manhours, as well installation and maintenance. Less downtime, more revenue.

For industrial motion control, CMZ Sistemi Elettronici provides FCT640 programmable plc controller: a new generation, modular, compact, and high-performing system based on CODESYS 3.5 with integrated I/Os is a great option to consider.

Its technological soul is fully conceived and developed by CMZ.

FCT640 integrates motion control solutions into a single and compact technological device. The controller is equipped with all the field buses used in the industry (EtherCAT, CANopen, ModbusTCP) and integrated modular I/O units, both digital and analog.

The choice of the OPC UA communication protocol is a coming soon implementation, to allow the system to be networked to the outside efficiently and safely by ensuring full connectivity with other devices as a relevant feature for Industry 4.0. interoperability.

The power of the processor, the presence of Ethernet and CAN ports and serial ports, alongside with a total memory capacity of over 1 GB plus an SD-Card, complete FCT640 technological equipment.

Dimensions mm: H 110 x W 57 x D 73. Weight gr: 300

To learn more about what we do and how we can help your industrial motion control requirements, please click projects, products & services.

Ti2 is currently very focused on working with its global partners to secure stock and avoid long delay times in delivering products to their customers. Together with our trusted partners, we are here to provide solutions.

Please click here to email us your inquiry, we would like to hear from you.

Article inspired by Siemens, CMZ, Ti2, and PIF