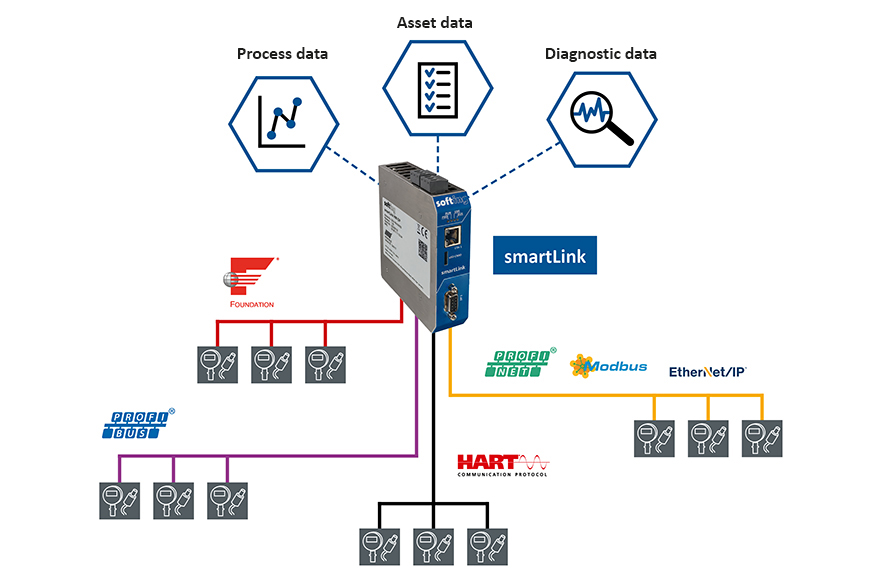

Modern communication architecture is required in controlling and managing the discrete and process manufacturing of plants which is able to aggregate their heterogeneous data. SmartLink from Softing facilitates interface-neutral data integration in complex production systems.

Transparent and standardised data

The issue with manufacturing technology is integrating existing with new to process data. Thus the struggle with innovations in this area of industry. However, with the advances of Industry 4.0 and the IoT changes the products and services in the field of manufacturing with modern technologies such as cloud storage, blockchain and rapid prototyping are offering truly novel opportunities pretty much anywhere along the value chain. And the basic building block of all the above is the coherent integration of production data.

Higher-level systems forms the basis for all processing, analysis and visualization steps in the transparent integration data downstream applications which is aimed at monitoring and optimization. Information that drives decision-making about process optimization and an increase of OEE is from all the aggregated data from all the devices installed.

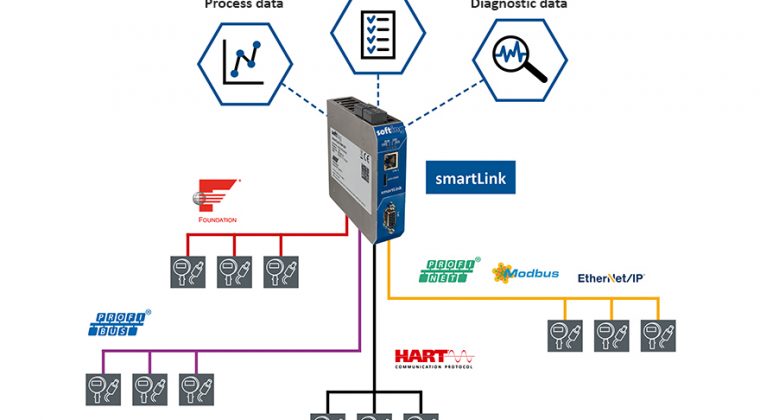

For automated facilities who uses PROFIBUS, the standard for fieldbus communication, the communication architecture is unable to meet the basic requirements of IoT applications. Which is where the smartLink takes over. All the data are provided using open, standardised interfaces such as HART IP, OPC UA and FDT.

Key data for process optimization:

These data provides evidence of the interoperability between controller and field devices while offering important insights into the configuration and condition to the overall system. Notifies quickly when there’s a change, locations and the causes of the problems is easy to pin down. Which keeps it downtime to a minimum that allows precise forecasting for further advances in modernising your plant.

SmartLink is an ideal asset perfect for integrating any implemented automation components without causing operational problems for existing installation. Which the connectivity of industry 4.0 becomes possible for the new and establish PROFIBUS DP networks and cost effective in time and money.

In a summary:

Once installed, smartLink starts collecting data from the whole system: data that are essential for cost-effective operations, reliability and modernization – and ultimately for the competitiveness of the operating company.

Please contact us for further information